Here’s our little underwater player for swimmers, Sonr Music, almost ready. The music is playing, swimmers are excited, and pre-sales are growing!

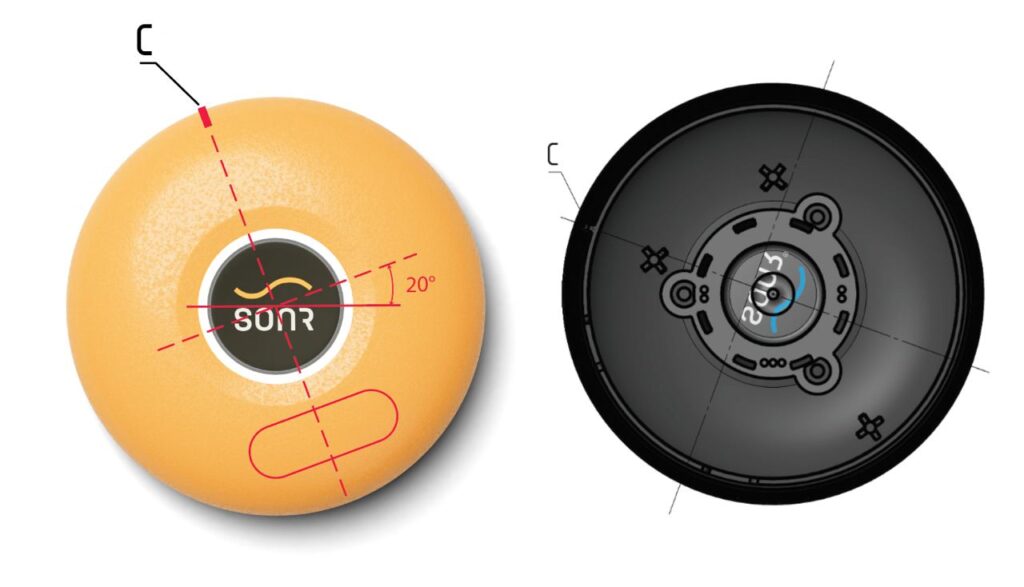

Note: Sonr Music is an underwater player that transmits sound via bone conduction directly into the middle ear. Therefore, you can place it anywhere under your swimming cap. It’s comfortable, it doesn’t press on your temples like all other headphones, and most importantly, it does NOT sink!

But there is a BUT. The founder is a droner. It happens. He stops production, sales, and the engineers are given the super-important task of not selling the device until…

— It starts floating horizontally!

Are you serious? Dima, come on, who cares how it floats? No one pays attention to it! We’re already out of deadline!!!

But the founder remains unconvinced.

— We can’t allow our extraordinary player to float around like a piece of crap without balance.

Pfft. Okay. Let’s get to work. We filled a basin with water, unpacked a couple of players, and started sorting things out.

That’s it, the battery pulls it to one side. Let’s get some small nails in the other side and get it balanced.

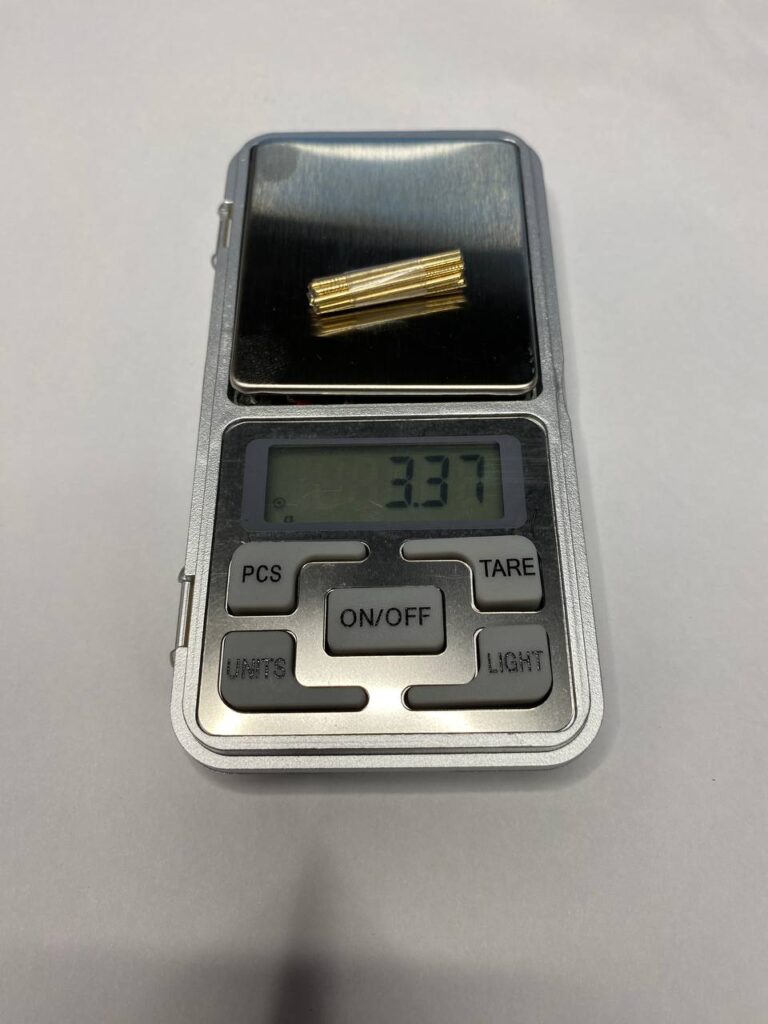

Ship righted, captain! Aye, smooth sailing! We measure the weight and look for an alternative for the nails. We’re trying different materials. Wolfram is ideal because of its density, but it’s expensive and fragile. We opt for stainless steel – dense, thrifty and nifty!

We choose the length of the rod and measure the bend very accurately.

We fix the rod with glue and test it – seal the casing and start shaking it, dropping it on the floor, dipping it. We open it up and realize it’s come loose.

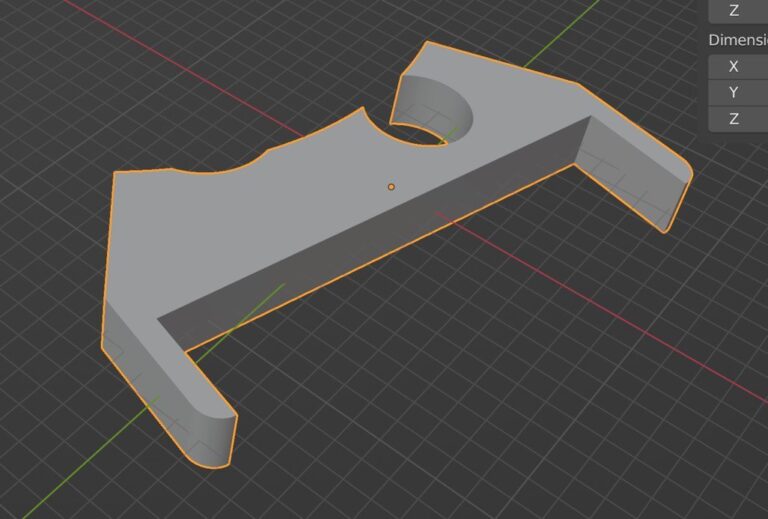

This means we need a special fix, so we start 3D modelling.

We determine the perfect place for the fixture.

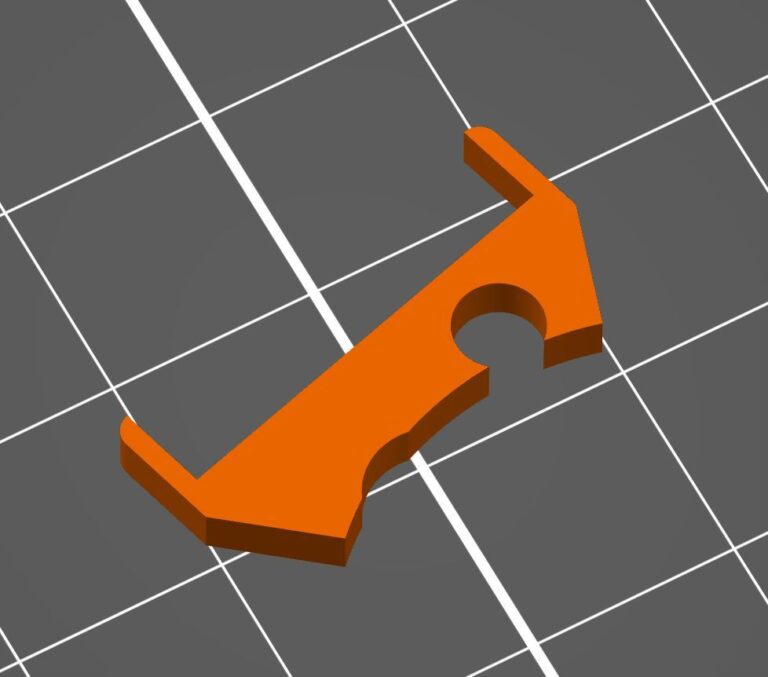

We print the prototype and solder it into the casing.

Assembling the casing and sending it for final tests – vibration and falling on the tiles. It works! We then wrap it in a condom and send it for water testing.

Bingo! Now even a sheet of paper on water is more crooked than Sonr. Congratulations, team – the device is ready for production!

And now the question comes up – was it worth stopping the team’s work for two weeks and spending thousands of dollars for a small righting of a few degrees?

To me, the answer is obvious.